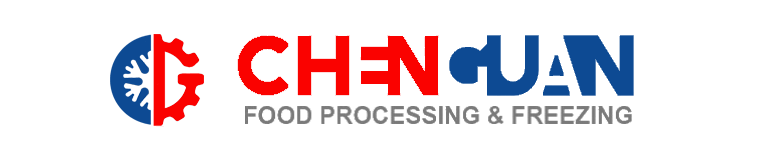

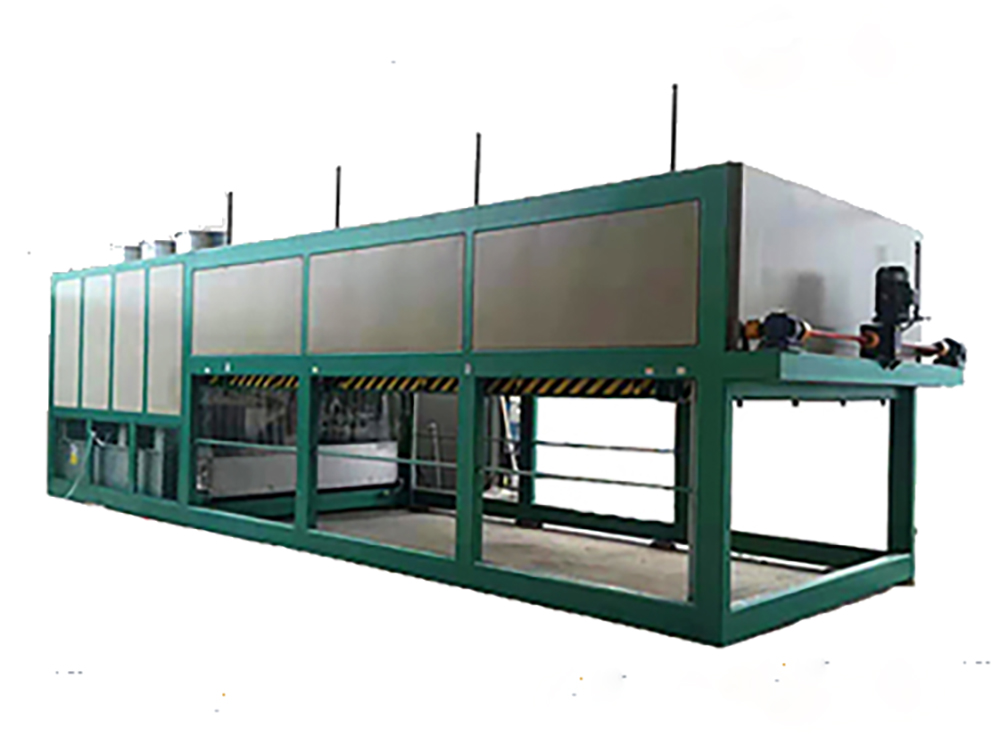

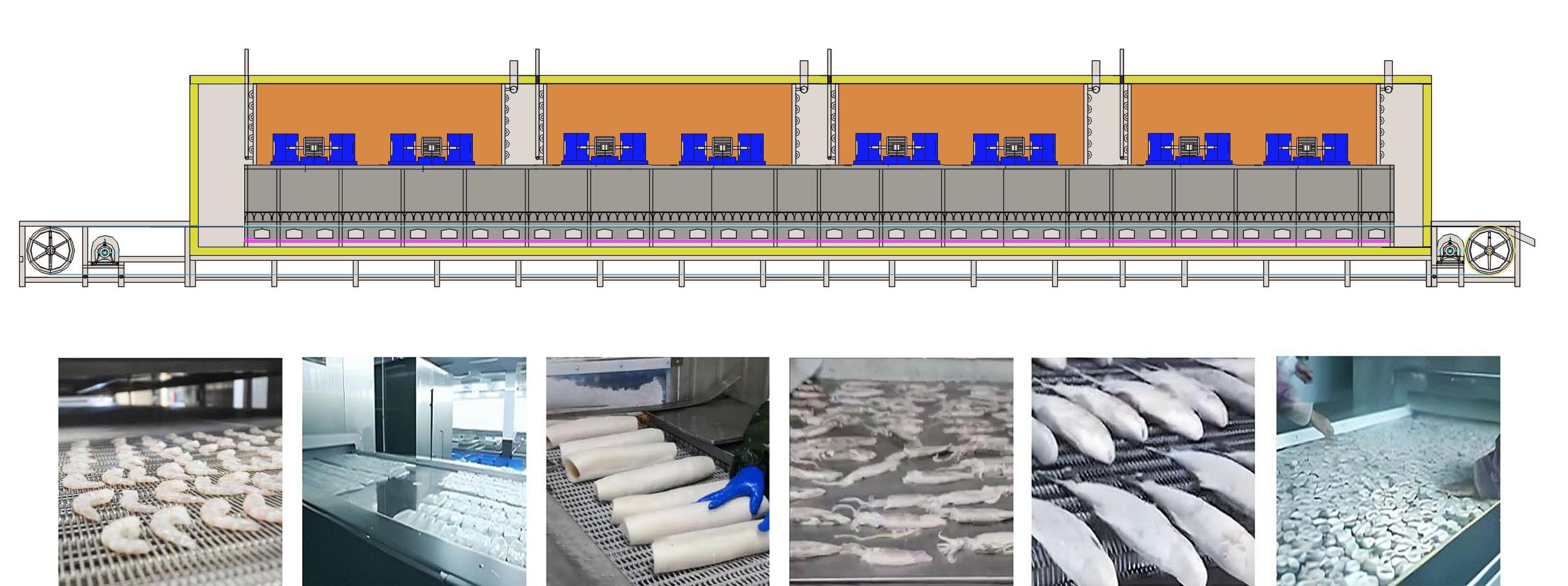

Impingement freezing is a process that freezes foods on the belt using high-speed airflow directed from both above and below. It has emerged as a popular new freezing method in recent years. This technique is widely used in the deep-freezing processing of meat, poultry, seafood, and other quick-frozen foods. Its short freezing time enables extremely low dehydration loss.

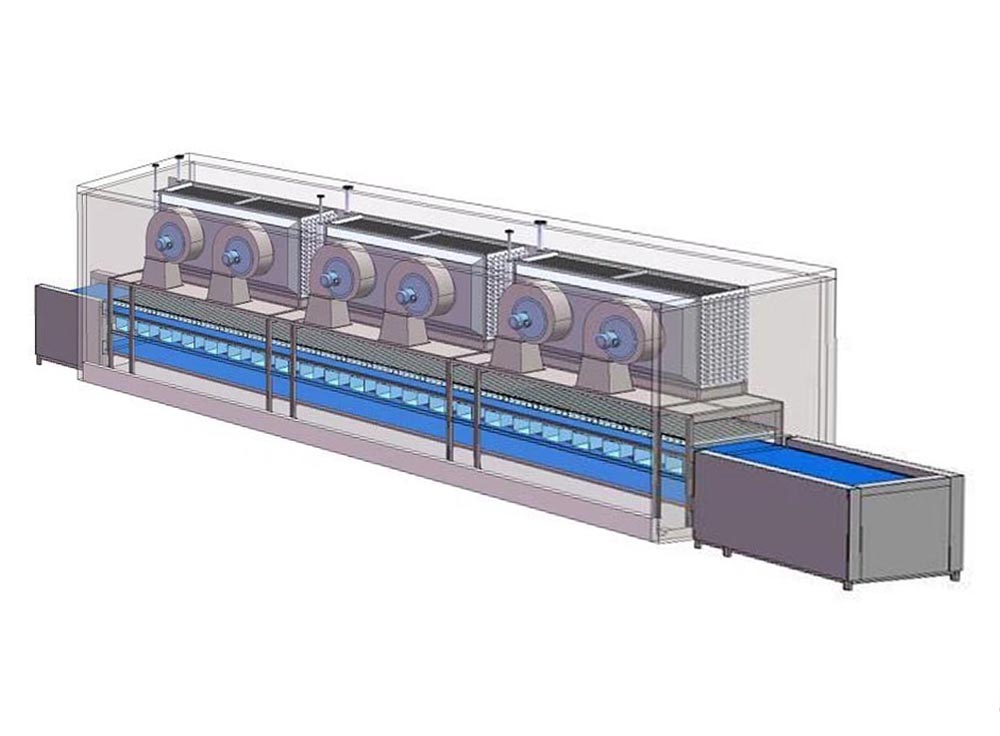

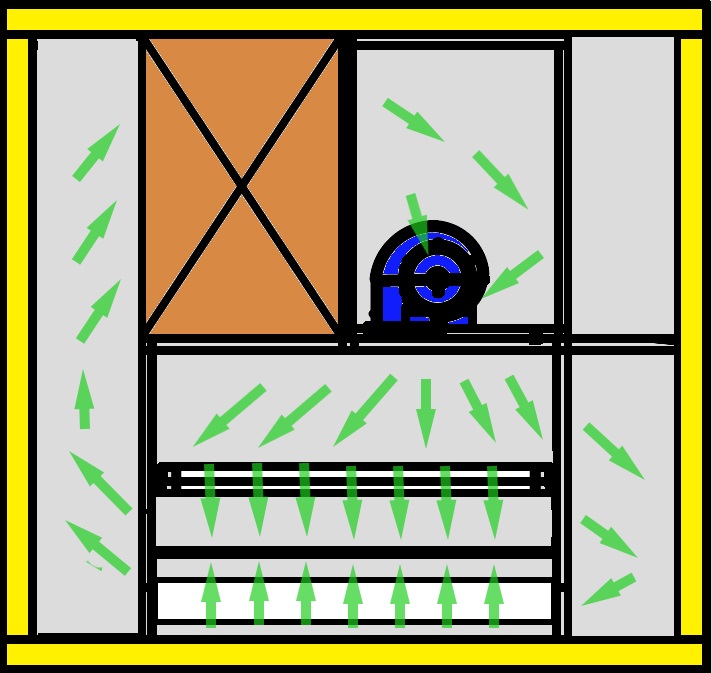

The impingement tunnel freezer equips centrifugal fans instead of axial fans, optimising airflow direction to reduce freezing time and enhance freezing efficiency. The centrifugal fan generates high-pressure air, which is further pressurised through an upper and lower air pressure injection system. This air is then propelled at high velocity onto the conveyor belt for quick freezing. Both the belt and the food materials upon it are swiftly cooled by the cold air. Compared to conventional tunnel freezers using axial fans, the impingement-type design reduces freezing time by 20–40% while lowering food dehydration loss by over 50%.

Features

• Equip with some high-speed centrifugal fans delivering high air pressure and rapid airflow.

• Upper and lower air pressure injection system enables swift and efficient heat transfer.

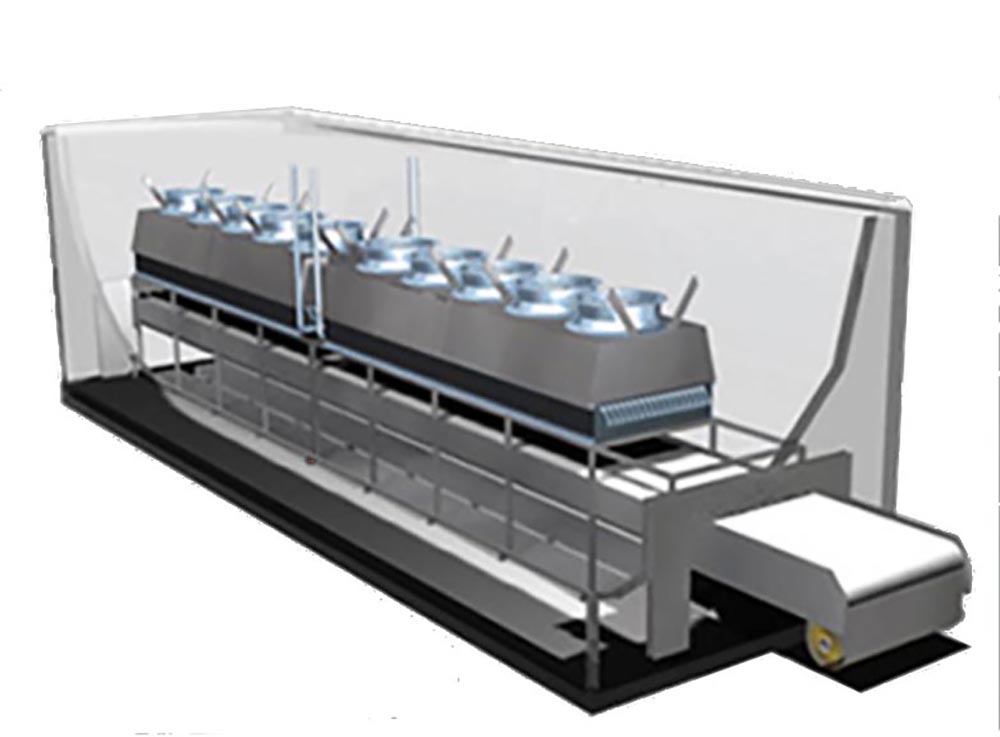

• Hygienic welded stainless steel construction。

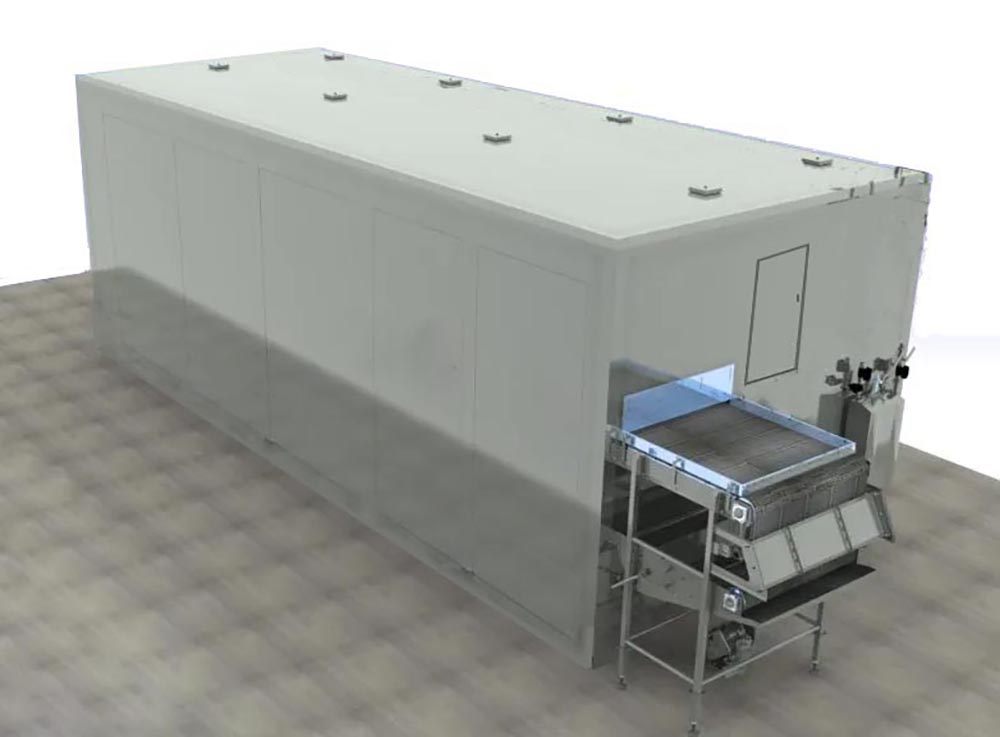

• Innovative fin design extends defrosting interval to 12-16 hours.

• It is available to choose SUS mesh belt or SUS flat plate belt.

• Non-slip sloped floor facilitates effective drainage.

Product Parameters

Product inlet temp: +15℃

Product outlet temp: -18℃

Feeding density: 5.5 Kg/m²

Freezing capacity: 500-2000kg/h

Refrigeration consumption:50-100kw/ton

Freezing time: 20-40 minutes

Inside temperature: -36±2℃

Refrigerant: R717,R22,R404a,R507c

Defrosting: Water,electric,hot gas

Voltage: 380V or customized

Available Foods

Bakery, cheese, dairy, poultry and seafood, chicken, meat, langoustine, clams, pork, shrimp and etc.

PDF Catalogue